Why are there inner rotor and outer rotor types in permanent magnet motors? The difference lies in which part rotates—the inside or the outside. If the inside rotates, it’s an inner rotor structure. If the outside rotates, it’s an outer rotor structure.

Let’s take a closer look at the differences between these two types.

Inner Rotor Motor

Structure

In this type, the stator is on the outside and includes the core and windings. The rotor is on the inside and consists of the rotor core and permanent magnets. Surface-mounted PMSMs, embedded PMSMs, and built-in PMSMs all fall under the inner rotor category.

Features

Cooling advantage: Heat from rotor copper loss transfers directly through the shaft to external cooling systems. In a 50kW motor, this design can reduce temperature rise by 15–20°C.

Dynamic response: With a low moment of inertia (typically under 0.1 kg·m²), it achieves millisecond-level response in CNC machine tools.

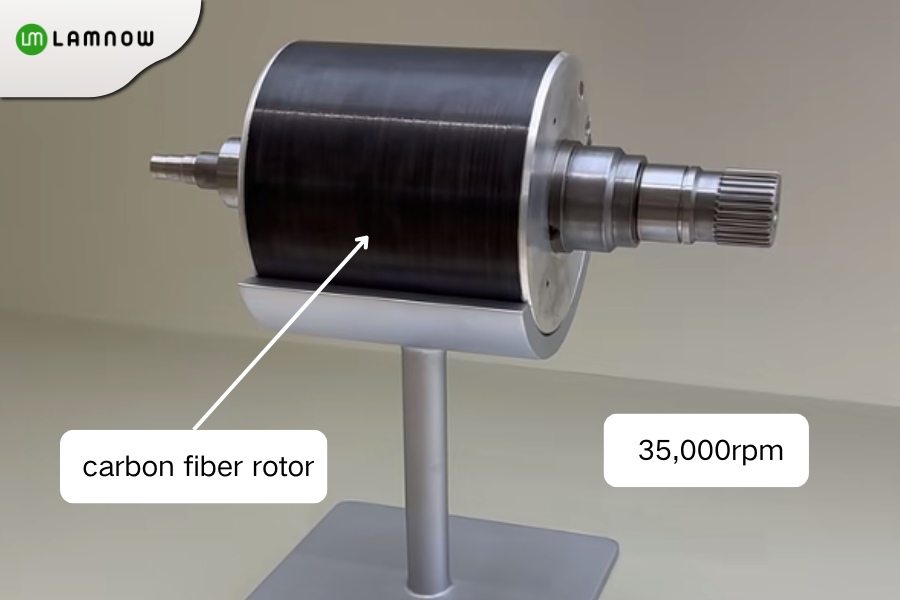

High-speed compatibility: Rotors with carbon fiber banding can operate stably at over 20,000 rpm. The inner rotor setup is ideal for speeds around 9,000 to 12,000 rpm.

Applications

Tesla’s Model 3 uses an inner rotor drive motor with oil cooling. It delivers 220kW of continuous power in just 0.05m³.

In precision machining, Switzerland’s Starrag Group has pushed spindle motor speeds to 40,000 rpm.

Finished with inner rotor motors? Let’s move on to the fascinating world of outer rotor motors.

Outer Rotor Motor

Structure

In this structure, the stator sits inside and includes the core and windings. The rotor is on the outside, containing permanent magnets, rotor core, and an outer shell.

Features

Simple construction: Outer rotor motors have a simpler build, which makes them easier and cheaper to manufacture and maintain.

Space efficiency: Take hub motors, for example. By integrating motor and wheel, they eliminate traditional transmission systems. This boosts transmission efficiency to 98%.

High-speed capability: The upper speed limit of outer rotors can reach around 30,000 rpm.

Cooling concerns: These motors generate more heat during operation. Effective cooling is essential to ensure safe and stable performance.

Control complexity: Outer rotors usually operate at lower speeds, which makes precise control more difficult. They often require advanced strategies like vector control or direct torque control.

Applications

As motor efficiency standards rise, low-speed, high-torque outer rotor motors are gaining popularity in industrial use. They offer high torque density and excellent energy efficiency.

DJI’s Inspire drone series uses outer rotor brushless motors. These motors deliver 8kg of thrust with only 400g of weight.

Germany’s ZF Group recently launched the eWheel system, which integrates outer rotor motors with active suspension—pioneering a new era of distributed smart chassis systems.

Comparison Table: Inner Rotor vs. Outer Rotor Permanent Magnet Synchronous Motor

| Performance | Internal Rotor Motor | External Rotor Motor |

| Structure | Rotor inside, surrounded by stator windings | Rotor outside, encasing the stator |

| Size and Design | Larger magnets, increased axial dimensions | Smaller magnets, reduced axial dimensions |

| Torque Density | 3-5Nm/kg | 5-8Nm/kg |

| Speed Range | 500-20000rpm | 100-5000rpm |

| Cooling Efficiency | Active (liquid/oil cooled) | Passive (via housing) |

| Axial Length Ratio | Length-to-diameter 0.8–1.2 | Length-to-diameter 0.3–0.6 |

| Applications | High-speed applications (power tools, EVs, turbines) | Low-speed, high-torque uses (e-bikes, scooters, wind turbines) |

In the wave of Industry 4.0, choosing between inner and outer rotors is no longer just about structure—it’s a system-level design decision. Engineers are redefining the art of rotation through innovation. This silent battle of technology is driving industrial progress to new heights.

Custom Inner and Outer Rotor Lamination Core — Choose Lamnow

Lamnow is a professional Chinese manufacturer of motor cores. We specialize in stator cores, rotor cores, amorphous cores, transformer cores, and generator cores.

For prototype inner and outer rotor cores, we offer laser cutting, wire EDM, adhesive bonding, and laser welding with a lead time of 15–25 days. For mass production, we can provide continuous stamping, compound stamping, spiral stamping, and axial stamping based on your design.

If you need custom or standard mold motor cores, feel free to contact us anytime!