Why do axial flux motors use an SMC core? Because of their high power density and short axial length, axial flux motors are widely used in applications such as electric aviation propulsion, wind power generation, and flywheel energy storage systems.

What Is Soft Magnetic Composite (SMC)?

Soft Magnetic Composite (SMC) is a magnetic material made by pressing iron-based powders together with an electrically insulating binder.

SMC materials are produced using powder metallurgy processes, where each magnetic particle is electrically insulated from the others. This insulation significantly reduces eddy current losses, and gives SMC isotropic magnetic properties.

Compared with traditional silicon steel laminations, SMC materials support more complex three-dimensional magnetic flux path designs, while maintaining good electromagnetic performance and sufficient mechanical strength. This allows SMC to meet the requirements of a wide range of applications.

Common SMC material suppliers include Höganäs, with typical material grades such as Somaloy® 1P, Somaloy® 3P, and Somaloy® 5P.

Manufacturing Process of SMC Cores

Powder Preparation

The most commonly used raw materials are high-purity iron powders or alloyed iron powders. Each powder particle is uniformly coated with an extremely thin electrical insulation layer.

The purpose of this insulation layer is to interrupt electrical current paths between particles after compaction, thereby significantly reducing eddy current losses.

The uniformity and stability of the insulation coating are critical factors that directly affect the final magnetic performance and core loss characteristics.

Pressing and Forming

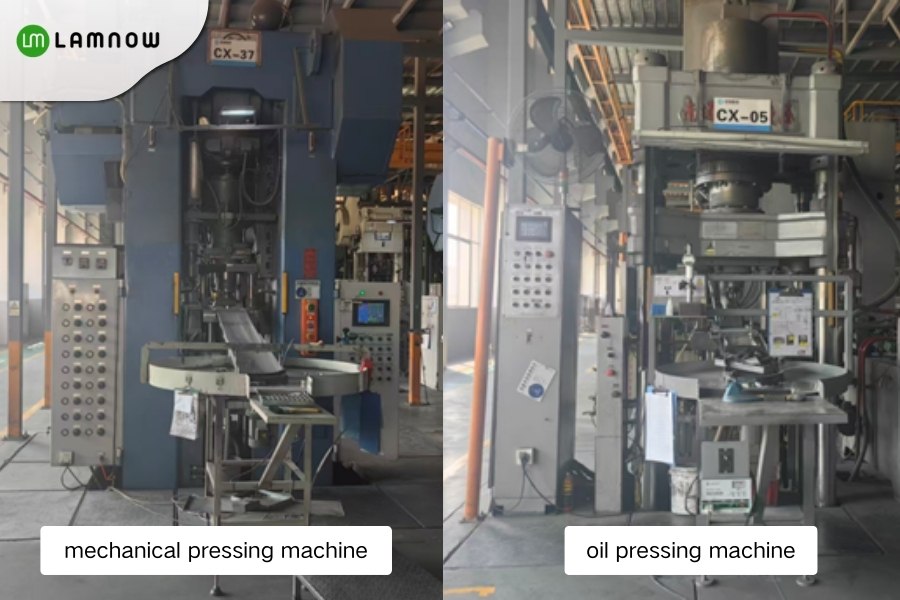

After preparation, the magnetic powder is loaded into a dedicated mold and cold-compacted under high pressure, typically reaching several hundred MPa.

In our production, we commonly use mechanical presses and hydraulic presses, with press capacities ranging from 100 tons to 240 tons.

One of the key advantages of the SMC process is that the core can be pressed directly into a near-net-shape geometry.

Unlike silicon steel laminations, which require stamping and stacking, SMC cores can be formed into complex three-dimensional structures in a single step, such as radial magnetic paths and irregular tooth geometries. This significantly increases design freedom.

Sintering

After compaction, the core undergoes thermal treatment or low-temperature curing. The primary purpose of this process is to fully cure the binder within the material.

The curing process is typically followed by water cooling and is generally divided into four stages.

Thermal curing improves the bonding strength between powder particles while stabilizing the insulation layer.

The curing temperature is usually lower than the annealing temperature of traditional silicon steel, in order to avoid damaging the insulation coating.

A properly controlled thermal curing process achieves a balance between mechanical strength and magnetic performance.

Post-Processing

In some applications, additional post-processing steps may be applied, such as surface coating, moisture protection, or localized machining. It should be noted that SMC cores are generally not suitable for large-area CNC machining, as machining can damage the insulation between particles and negatively affect magnetic performance.

Therefore, SMC cores should be designed as near-net-shape components from the beginning.

SMC Core Windings

SMC cores typically use concentrated flat-wire winding.

In practical production, winding is usually performed using preformed coils, or by manual or semi-automatic concentrated winding processes.

Compared with traditional silicon steel laminated stators, SMC cores are not constrained by inter-lamination stacking structures. This allows more efficient use of winding space, which helps to increase the copper fill factor.

After winding, the coils are usually subjected to impregnation or encapsulation, in order to enhance mechanical strength, insulation performance, and thermal dissipation.

How Does YASA Apply SMC Technology?

In fact, YASA technology is the result of continuous technical evolution, which can be roughly divided into three stages.

First Generation

The first-generation products were traditional axial flux motors with an R–S–R structure, featuring a yoked, integral stator. The stator windings were wound vertically around the teeth.

This structure relied on the “wound lamination” manufacturing process of silicon steel.

Second Generation

In the second generation, the stator yoke was reduced to a minimal size, serving only as a connection between individual teeth. The windings were arranged in a flat, concentrated configuration on the teeth.

The development of this structure depended on the maturity of SMC stator compaction technology.

Thanks to the isotropic magnetic properties of SMC materials, designers were able to break free from the constraints of silicon steel stamping processes and create optimized three-dimensional stator structures, greatly improving space utilization.

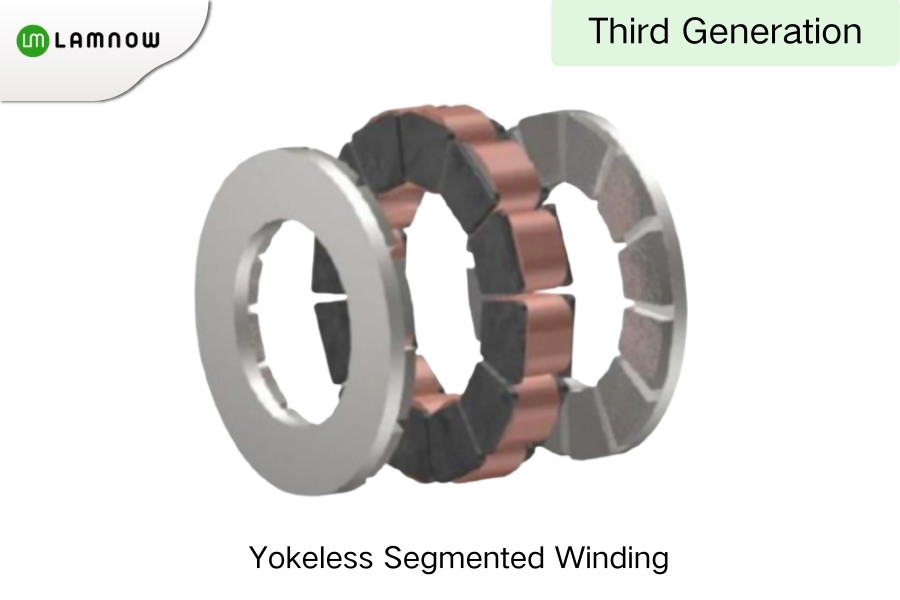

Third Generation – The “YASA” Structure

The third generation is the well-known “YASA” structure, which completely eliminates the stator yoke, maximizing torque density.

The evolution of this structure is inseparable from breakthroughs in structural design and manufacturing processes.

The core challenge solved by this technology is how to integrate segmented stator teeth into a complete assembly.

Why Are More Axial Flux Motors Using SMC Cores?

Reduced eddy current losses:In high-frequency applications above 10 kHz, SMC cores can reduce losses by approximately 30%–50%.

High design flexibility

Reduced part count

Improved dimensional accuracy

High power density

Suitable for high-speed motors (>20,000 rpm)

Low noise and low vibration

Lightweight

How Do SMC Cores Achieve High Design Freedom and Low Core Loss? By combining insulated soft magnetic powders, high-pressure compaction, and low-temperature curing, SMC cores can be formed into complex three-dimensional magnetic structures without the need for lamination stacking. This makes them particularly suitable for high-frequency and high-power-density motor applications.

SMC Lamination Core – Choose Lamnow

Looking for a reliable manufacturer of SMC cores for axial flux motors?

Lamnow specializes in motor core manufacturing and can mass-produce SMC cores for axial flux motors.

We are equipped with both mechanical and hydraulic compaction presses across a wide range of tonnages, as well as complete thermal treatment facilities, enabling us to cover the entire SMC manufacturing process.

Feel free to contact us to obtain a professional solution.