Do you know why W-Pin flat wire winding is becoming a focus in the electric motor industry? Compared with the mainstream Hair-pin winding, what makes W-Pin winding different?

In this article, we will explain what W Pin is, its manufacturing process, advantages and disadvantages, and real application cases. This will help you understand this advanced technology quickly.

Background and Development of W-Pin

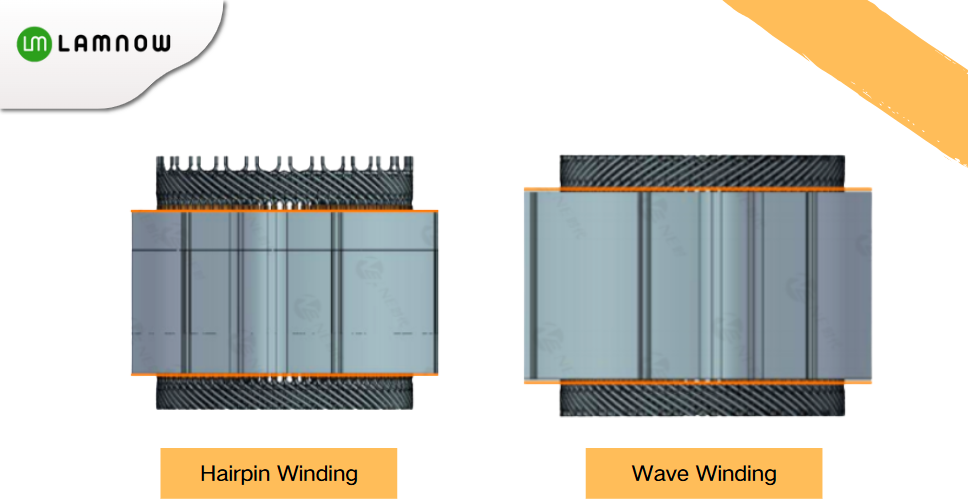

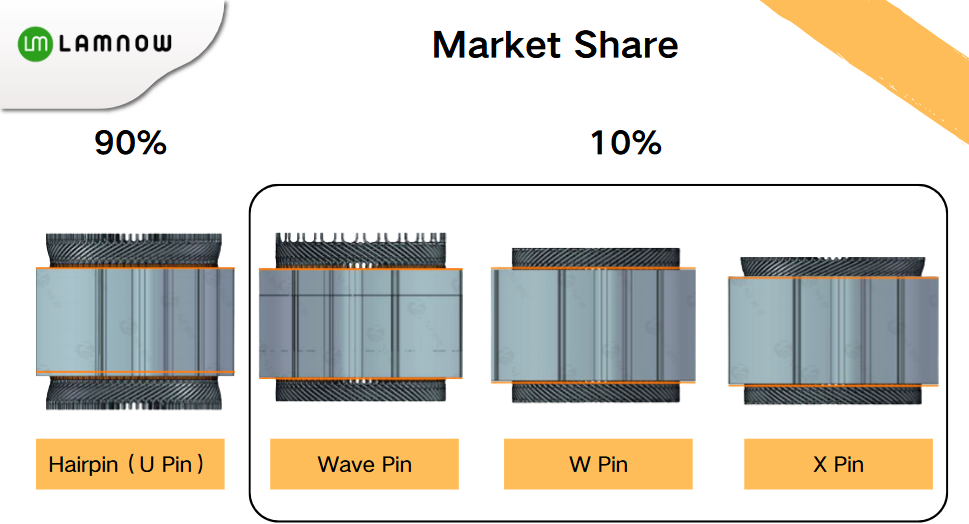

With the continuous evolution of flat wire motor structures, winding forms have become more diverse. Hairpin winding is still the most widely used form. It holds about 90% of the market share thanks to its mature process and cost advantages. Other forms, such as I-pin and W-pin, only account for about 10%.

However, the industry has not stopped innovating. New winding forms like i-pin, U-pin, X-pin, and W-pin are gradually emerging. Among them, W-pin is considered one of the most important development directions for the future. Although the manufacturing process is more difficult at present, the efficiency advantage is very clear, so it is receiving increasing attention.

What is W-Pin Winding?

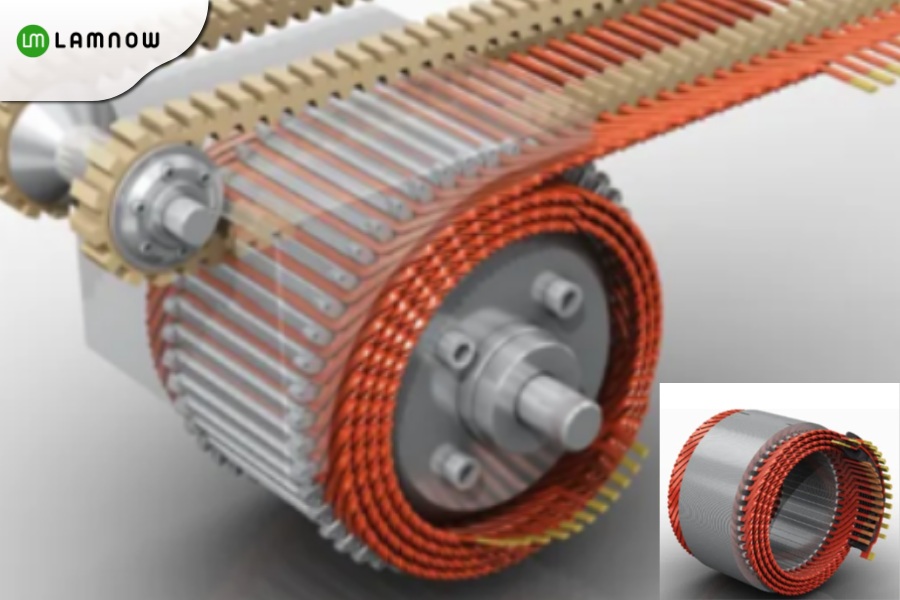

W-Pin, also called continuous hairpin / wave winding, is a special type of flat wire continuous wave winding. Compared to other types, W-Pin stators are about 30% shorter, and torque density increases by more than 50%.

In addition, W-Pin takes up less space than Hair-pin and is more suitable for the current 800V oil-cooled EV motor trend.

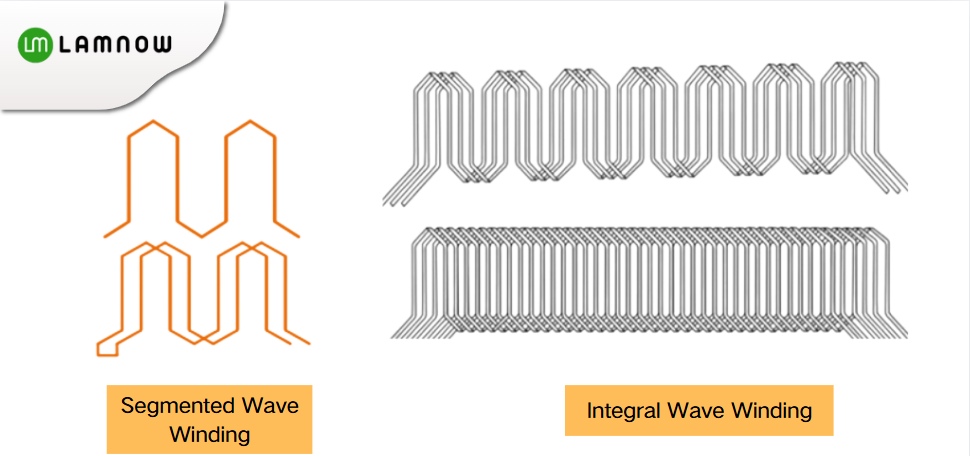

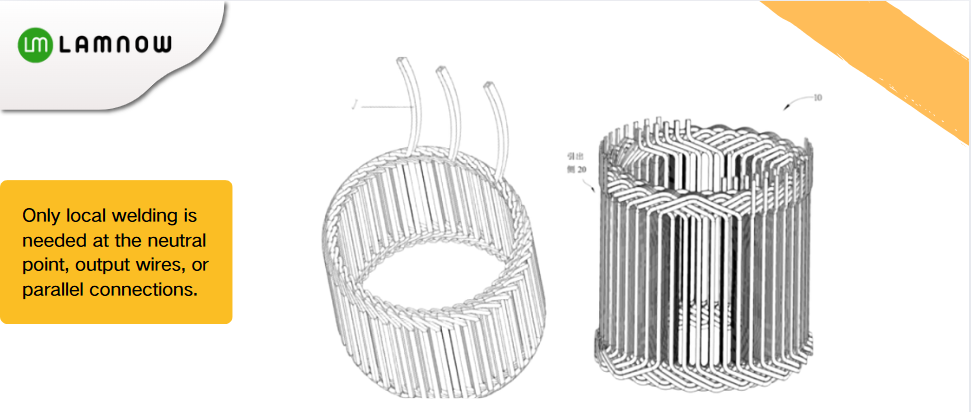

W-Pin can be divided into integral wave winding and segmented wave winding. After forming, the two ends of the winding require no welding, and the end height is lower.

The design fits well with multi-slot, multi-layer motor structures. However, the integrated forming of the coil is very challenging. The stator slot usually needs to adopt an open shape to allow the winding to be inserted radially.

W-Pin Manufacturing Process Flow

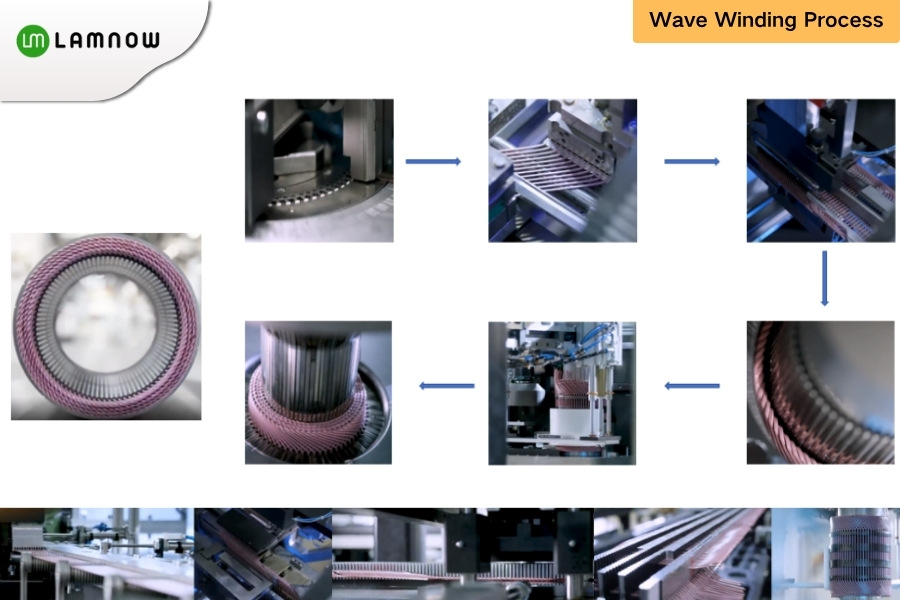

The W-Pin process flow includes: slot insulation paper insertion, wire forming, wire arranging, wire winding, coil insertion, slot cover installation, three-phase wire welding, varnish dipping, and final testing.

Wire forming: Feed the wire from the spool, straighten it, pull it, cut it, and form it once through stamping dies.

Wire arranging: Remove enamel, transfer, arrange wires sequentially on the combing fixture according to the winding method, press tightly, and inspect.

Copper Wire winding: Rotate the winding fixture, press and shape the coils, then transfer them to the inner supporting fixture.

Coil insertion: Use a robot to press the coils from the inner supporting fixture into the stator core.

Slot cover installation: Form the slot cover paper into a C-shape and insert it into the slot of the stator core after coil insertion to wrap the copper wires.

There is also another method. First, wind the coil on a tooth shaft, and then install an outer iron core sleeve. This method avoids coil deformation and damage after being pressed into the stator core and also solves the problem of slot openings. It can reduce cogging torque. But there are trade-offs. Leakage flux increases and an extra air gap appears, which means more magnetic material is needed.

W-Pin Manufacturing Challenges

1.During wire forming process, uneven stress on the copper wire can cause stretching and damage.

2.After straightening, a single wire can be close to 10 meters long, but the length shortens after forming, so the coil tends to sag and bend during forming and transferring.

3.Formed wire shapes are often unstable, making it difficult to meet the requirements of subsequent arranging and insertion processes.

4.The stator winding method greatly affects wire arrangement. Cross arrangements are complex and difficult to automate.

5.It is hard to avoid damaging the enamel on the copper wires while maintaining accuracy in wire positioning and tightness.

6.The slot cover is not easy to insert near the insulation paper edge. There is a risk of protrusion into the stator inner diameter and poor insulation.

W-Pin Process vs. Hairpin Process

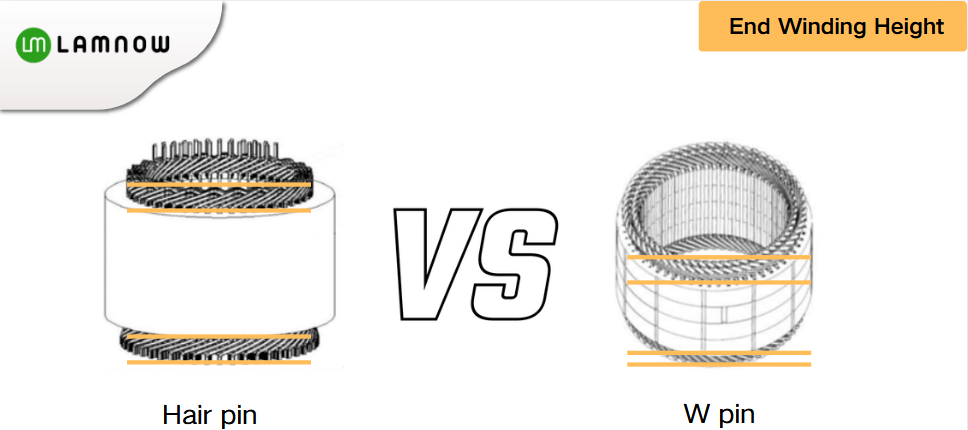

1.W-Pin wave winding has no weld points at either end, saving the straight sections required for the welding process. It also eliminates the coating step. Under the same wire diameter and span, the end height of W-Pin products can be significantly reduced.

2.W-Pin products require no flaring or end welding. For a 10-layer W-Pin product, the end diameter is about 20 mm shorter than that of a Hair-pin product. Hair-pin requires at least a 2 mm gap between weld points for insulation, which makes the winding size larger.

3.W-Pin does not require cutting off wire heads, which improves copper utilization. Hairpin cutting generates waste copper.

4.W-Pin eliminates welding, reducing quality risks. Hair-pin has many weld points, so its quality control is harder, and its yield rate is lower.

5.Without enamel removal, cutting, or welding steps, W-Pin’s cleanliness is easier to control. This makes it more suitable for oil-cooled motors. Hair-pin cleanliness control is much more difficult.

Advantages and Disadvantages of W-pin

Disadvantages:

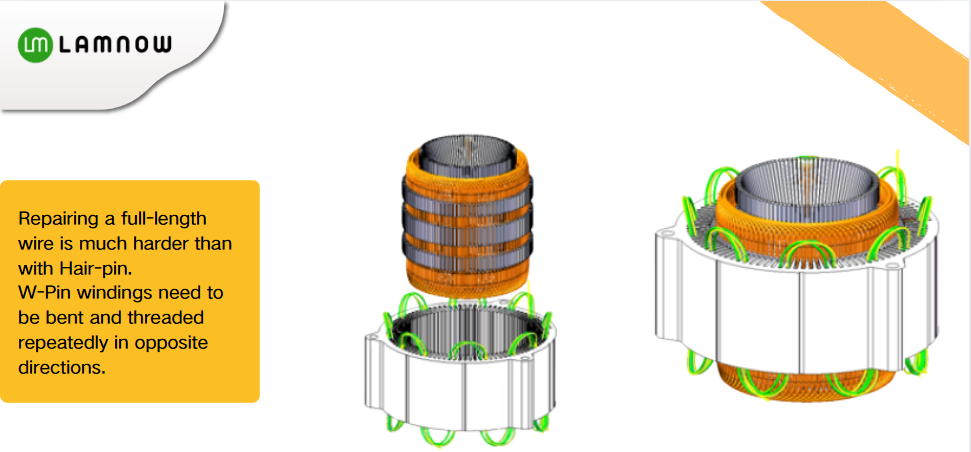

1.If insulation or other problems occur in W-Pin windings, repairing a full-length wire is much harder than with Hair-pin. Multi-layer braided structures often cannot be repaired.

2.W-Pin windings need to be bent and threaded repeatedly in opposite directions. To thread each slot smoothly, the straightness after bending and the insertion direction must be ensured.

3.The internal wires of W-Pin are difficult to control because of rebound, making it challenging to keep consistency in the braided end structure.

Advantages:

1.The W-Pin winding end has no Hair-pin weld points or bus bars. Only local welding is needed at the neutral point, output wires, or parallel connections. This eliminates many steps and reduces process cost.

2.The end of W-Pin windings is much shorter because it requires no welding.

3.W-Pin windings have better NVH performance. They reduce torque ripple, which is the periodic increase and decrease in torque as the motor shaft rotates. This allows for smoother operation.

Applications

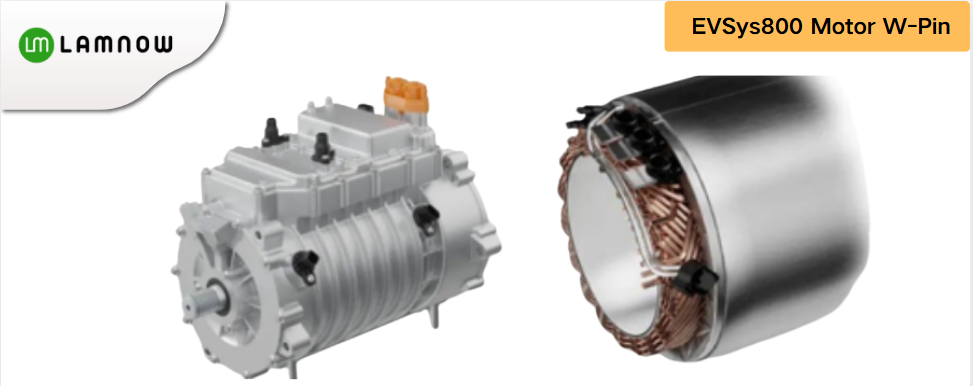

ZF’s EVSys800 rare-earth-free electrical drive uses W-Pin braided winding technology. This allows the drive system to save 50 mm in length, making the electric drive system more compact.

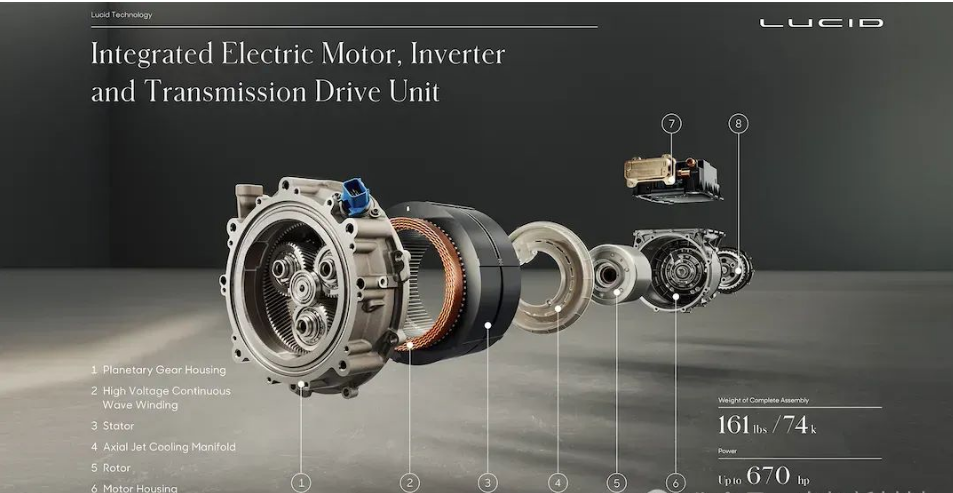

Lucid also uses multi-layer flat wire W-Pin windings. Its stator has only 24 weld points connected to the inverter. The motor winding is braided separately and then inserted into the stator core to complete the stator. Each stator slot contains eight flat copper wires. Lucid is the world’s first manufacturer to mass-produce 8 flat wire W-Pin stators.

It is worth mentioning that Lamnow also manufactures W-Pin flat wire stator winding, i-pin winding, and hairpin motor stator winding for new energy vehicles driven motor. Please feel free to contact us if you have related business needs.